The design of the product’s packaging should be developed during the early-stages of a medical device’s creation-phase.

Outside of the validation and regulatory criteria’s that both the medical device and its packaging must meet - the primary intention of the packaging is to keep a sterile barrier until the final medical device is in usage. This means the safe delivery of the product from the manufacturing phase to final use with its patient.

When a medical device’s packaging is not considered a priority early-on, the manufacturer may be faced later-on by a number of problematic and costly challenges.

Most importantly, it may lead to delays during the Sterilisation Validation stage

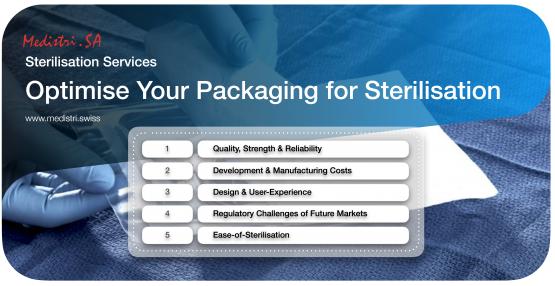

All adjustments to the medical devices’s packaging should be made early-on. And in order to increase cost-efficiency and reduce bottlenecks - there are a number of considerations that need to be taken into account.

1️⃣ The Packaging’s Physical Quality, Strength & Reliability

2️⃣ The Development & Manufacturing Costs of the Packaging

3️⃣ The Packaging’s User-Experience

4️⃣ Regulatory Challenges of Future Markets

5️⃣ The Package Ease-of-Sterilisation

Medistri’s team has gathered more than a decade of experience working with the world’s most innovative healthcare companies and helping them scale globally.

Working early on with Medistri’s Sterilisation Team during the product development process will help prevent potential costly failures.

In addition, it will also help prepare your validation timeline, optimise resources, discover complexity areas and deploy you final product according to your specific vision.

🎯 To learn more about our contract sterilisation services, visit our website at www.medistri.swiss or directly contact our team at contact@medistri.swiss.

- The Medistri team

#Medistri