(Download: Product Assembly Services in PDF by Medistri)

From Early Prototype to Industrial Readiness

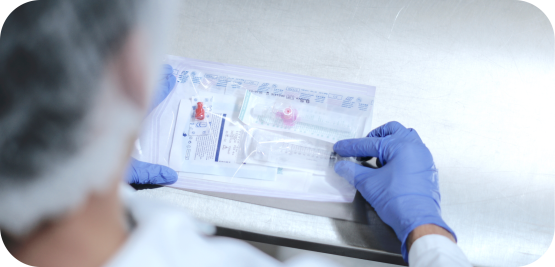

Before a medical device or pharmaceutical product can enter pre-clinical evaluation, it must first exist as a consistent and reliable physical product. At this decisive moment in development, product assembly transforms design intent into tangible reality shaping how a product will be tested, refined, validated, and ultimately industrialized.

At Medistri, product assembly is delivered by our dedicated manufacturing department, fully synchronized with our packaging, sterilization, and laboratory teams. This integrated approach is specifically designed to support:

- Low-scale manufacturing

- Early-stage prototyping

- Custom product assembly

- Medical and pharmaceutical kit packing

Our objective is to enable early-stage innovators to move from concept to credible pre-clinical material, while preparing a smooth transition toward industrial production.

A Structured Assembly Process Built for Development

In early development, assembly is not merely an operational step. It begins with technical clarification, ensuring that specifications, component lists, tolerances, and packaging constraints are fully defined before any physical work starts. These parameters determine how assembly can be performed, repeated, and documented.

Medistri structures assembly around six controlled stages:

- Technical definition and preparation: Clarification of product configuration, materials, and packaging requirements prior to execution.

- Packaging selection: Alignment with downstream needs such as transport, testing, sterilization compatibility, and storage stability.

- Incoming component inspection: Verification of conformity, material quality, and traceability against defined specifications.

- Preparation, assembly, and packaging: Execution under controlled conditions, including cleaning or disinfection steps where required.

- In-process and final quality control: Continuous verification of configuration accuracy, batch consistency, and documentation integrity.

- Final delivery and transfer: Seamless handover to logistics, laboratory testing, sterilization, or pre-clinical evaluation.

Originally designed for full manufacturing environments, this structured framework is particularly powerful during early-stage development, where consistency and representativeness are essential for meaningful testing.

Assembly Designed for the Pre-Clinical Phase

Pre-clinical studies depend on products that faithfully reflect the intended final design. Variability introduced during assembly can compromise:

- Functional and mechanical testing

- Stability and aging evaluations

- Sterility and packaging performance

- Regulatory documentation consistency

By applying a controlled, traceable assembly process from the outset, Medistri ensures that early test articles remain aligned with both design intent and future production logic, reducing repeated testing, limiting development delays, and improving data reliability.

Integrated with Packaging, Sterilization, and Laboratory Services

A key differentiator of Medistri’s product assembly services is full synchronization across departments:

- Packaging expertise ensures compatibility with sterile barrier systems and transport validation.

- Sterilization planning anticipates EO or steam requirements early in development.

- Laboratory testing enables immediate access to bioburden, endotoxin, sterility, and material evaluations.

This integration creates continuity across the development workflow, reducing late-stage redesign and supporting a smoother transition toward validation and routine production.

Supporting Low-Scale Manufacturing and Custom Kit Assembly

Medistri’s assembly capabilities are intentionally designed for early-stage and emerging companies, where flexibility and speed are critical.

We support:

- Prototype and pilot-scale builds

- Clinical and pre-clinical material preparation

- Custom medical and pharmaceutical kits

- Small-batch, high-traceability production

- Rapid iteration aligned with design evolution

This environment allows innovators to develop, test, and refine their products without the constraints of large-scale industrial manufacturing.

Preparing the Transition to Industrialization

Beyond early assembly, Medistri plays a strategic role in guiding customers toward long-term manufacturing readiness.

As products mature, we help:

- Define scalable assembly and packaging logic

- Ensure documentation supports regulatory pathways

- Identify and select appropriate industrial manufacturing partners

- Facilitate a controlled and efficient technology transfer

This approach allows early-stage companies to progress confidently from prototype to industrial production, supported by a partner who understands both development agility and regulated manufacturing discipline.

To learn more about Medistri’s Manufacturing services, visit our website here or contact our team at contact@medistri.com.

– The Medistri Team

#Medistri

Medistri is Europe's leading independent contract sterilization company, founded in 2006 and headquartered in the heart of Switzerland. We are a global player providing essential infrastructure that powers healthcare innovation worldwide.

We serve customers of all sizes, from startups, university projects, and research institutes to Fortune 500 corporations, across Medical Devices, Pharmaceutical Packaging, and Biotech.

Medistri supports products at every stage of the lifecycle: pre-clinical development, go-to-market, and full industrialization.

Our fully integrated, end-to-end in-house solution allows our customers to focus on what matters most: engineering, innovation, and development, while we manage the critical back-end processes.

Our synchronized departments work together to provide a complete stack of services:

- Contract Sterilization & Validation Services

- Contract Laboratory Services

- Contract Manufacturing Services

- Logistics Services

- Consulting Services

We help you accelerate time-to-market, reduce barriers to scale, and deliver safer, more sustainable healthcare solutions to patients around the world.

Medistri’s Solutions for Products in Pre-Clinical Phase

During the pre-clinical phase, execution is essential to validate concepts, generate reliable data, and establish a strong foundation for regulatory approval.

Medistri serves as your integrated infrastructure partner, delivering a comprehensive portfolio of in-house Solutions optimized for R&D and proof-of-concept development.

Our solutions encompass R&D treatment cycles (custom sterilisation protocols), cleaning & reprocessing, product assembly, and packaging, alongside specialized testing including biocompatibility, extractables & leachables, sterile barrier integrity, environmental conditioning, laboratory analysis development, batch release, and regulatory consulting.

This vertically integrated model minimizes vendor coordination, expedites development iterations, guarantees data integrity and compliance from inception, and enables your team to prioritize core scientific and engineering advancements.

Positioning you for seamless progression to clinical trials and commercialization.

Frequently Asked Questions

1. What is the role of product assembly in early medical device and pharmaceutical development?

Product assembly transforms design concepts into physical test articles that can be evaluated during pre-clinical development. It ensures that early products are consistent, representative, and suitable for meaningful functional and performance testing.

2. Why is a structured assembly process important before pre-clinical evaluation?

A structured process reduces variability introduced during assembly and packaging. This helps ensure that test results reflect the product design itself rather than inconsistencies in how products were assembled.

3. How does early assembly influence pre-clinical testing outcomes?

Assembly decisions affect product configuration, material interactions, and overall consistency. Poorly controlled assembly can lead to unreliable data, repeated testing, or delays, while structured assembly supports reproducible and interpretable results.

4. When should assembly activities be aligned with future manufacturing and validation plans?

Assembly should be aligned from the earliest development stages. Early alignment helps maintain continuity between pre-clinical testing, validation strategies, and eventual routine manufacturing, reducing the need for late design or process changes.

5. How does Medistri support product assembly during pre-clinical development?

Medistri applies a step-based assembly workflow that integrates technical definition, quality control, and documentation. This approach helps ensure that early test articles remain aligned with design intent and future manufacturing requirements while supporting traceability and development readiness.