Sterilization Validation for Auto-Injectors

Auto-injectors play a critical role in drug delivery, combining convenience, precision, and patient safety in a single-use medical device. When brought to market, these devices must meet the highest standards of sterility and performance - especially when combined with biological or pharmaceutical products.

An Overview of Cleaning Validation & Cleanliness Testing for Medical Devices

Medical device manufacturers face increasing demands for fast product release, regulatory compliance, and cost control. At Medistri, we offer one of the most competitive and efficient laboratory services in the Swiss market, enabling you to accelerate time-to-market while maintaining the highest quality standards.

The Sterilization Validation Steps Aligned with ISO 11135

Bringing a sterile medical or pharmaceutical product to market requires more than a compliant label — it requires proof that your sterilization process is effective, consistent, and safe. Sterilization validation isn’t just a regulatory hurdle. It’s a methodical, traceable process that confirms your product can reliably meet the required Sterility Assurance Level (SAL) of 10⁻⁶, even under worst-case conditions. It ensures patient safety, regulatory acceptance, and operational readiness for routine production.

Innovating Laboratory Testing: New Alternatives to Animal Testing for Medical Devices & Pharma

At Medistri, we are committed to advancing healthcare through innovation in laboratory and sterilization services. As regulatory standards evolve and global healthcare companies look for faster, more ethical, and more predictive safety assessments, Medistri supports clients in transitioning from traditional animal testing toward validated in vitro and animal-free methods.

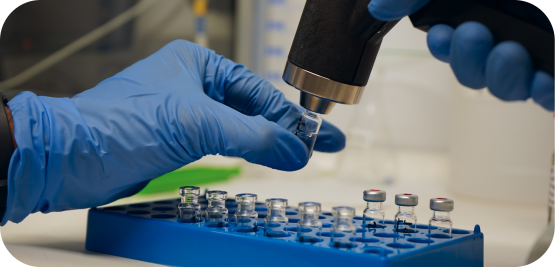

Sterilization Validation: Patient Safety and Product Integrity

From surgical implants to prefilled syringes, the products that reach healthcare professionals must be sterile - not by assumption, but by evidence. That evidence is generated through a process known as sterilization validation.

Ensuring Safety in Plastics and Food Contact Materials

At Medistri, we understand the growing concerns surrounding bisphenols - particularly Bisphenol A (BPA) - in plastics, polymers, and food contact materials. Bisphenols are synthetic compounds used extensively in the production of polycarbonates and epoxy resins. Due to their potential endocrine-disrupting effects, regulatory scrutiny has increased across multiple industries.

Medistri at PharmaDays 2025

Medistri is attending ThePharmaDays 2025 in Geneva, Switzerland from June 4 to 5, hosting a booth to cater client meetings, showcase its services and answer all questions.

Release of 2024 Carbon Emissions Report

At Medistri, our mission is to offer reliable, advanced services to healthcare companies while actively contributing to a healthier planet. We take full responsibility for the environmental impact of our operations - from sourcing materials and managing critical processes to delivering products to our customers.

New MyMedistri Features

As part of Medistri’s digital improvement, we are bringing new features for all customers through our dedicated platform: MyMedistri. Starting May 5 2025 and onward, all documents such as certificates, invoices and service-related activities will be handled exclusively via your MyMedistri account.

An Overview of BDDE Analysis by GC-MS

1,4-Butanediol diglycidyl ether (BDDE, CAS No. 2425-79-8) is a chemical compound widely used as a crosslinking agent in the manufacture of hyaluronic acid (HA)-based dermal fillers. Its primary function is to enhance the durability and longevity of these products by binding to HA molecules, increasing their resistance to enzymatic degradation. Given its extensive use in medical and cosmetic applications, ensuring the safety and quality of BDDE-crosslinked products is essential. A key aspect of this assurance lies in the accurate detection and quantification of residual BDDE in HA-based dermal fillers.